A while ago astute listeners noticed that inserting wire cables of different construction between power amplifiers and loudspeakers produces very noticeable changes in sound. Electrical current running between an amplifier and a loudspeaker is alternating and can be very large, both of which make construction of a wire cable quite relevant to performance. Large currents produce large power losses and compression of sound dynamics, while alternating current in full audio spectrum causes frequency dependant losses. Obviously, the longer the connecting wire cables, the more impact there is on the sound quality.

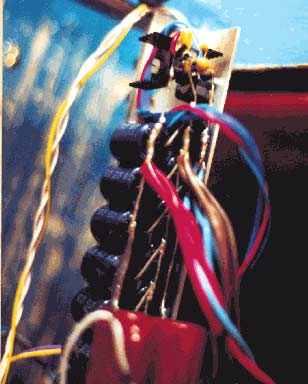

Often neglected element is the actual connection of the cable to the loudspeaker box and to the power amplifier. Usually the contact area of the connection in good loudspeakers and amplifiers is designed sufficiently large, but over time the contacts can loosen up and the contacts' surface deteriorates and oxidizes, providing very poor connection that produces terrible sound of otherwise good components. Reputable manufacturers use gold plating to reduce oxidation and recommend regular cleaning and tightening of the connections. The problem is, gold is a poor conductor that should not be used when large currents are involved, and most people are not keen on squeezing behind amps and loudspeakers to routinely clean contacts. Therefore, we at Dana Electro Acoustics feel a lot better way of obtaining an excellent and long term reliable contact is to silver-solder the connections.

Foundation #3: Power amplifiers must be as close to loudspeaker drivers as possible in order to minimize connecting cable length and subsequent cable induced sound degradations. Also, cable must be silver-soldered to the loudspeaker drivers and to the power amplifier outlets to avoid contacts deterioration and subsequent sound degradation.